Get Quote

News

- Application of Screw Conveyor in Cement industryThe screw conveyor is a powder material handling device, which has a simple and compact structure, reliable working performance, and low cost. It is currently widely used in the food industry, building material industry, chemical industry, transportation and other departments, such as cement and chemicals , Sand, flour, salt, etc. The use of tubular screw conveyors in cement transportation makes cement difficult to fly, which reduces waste and environmental pollution, and is a good cement transportation equipment. With the rapid development of road construction and continuous improvement of construction machinery, large-angle screw conveyors have become an indispensable and important part of concrete mixing equipment. Large-angle tubular screw conveyors are also often used on construction sites that use bulk cement. This article will briefly introduce the structural design and parameter selection of the high-angle tube screw conveyor. The large-angle screw conveyor is composed of three parts: the screw body, the inlet and outlet, and the driving device. The main body of the screw conveyor includes several parts such as head bearing, tail bearing, screw shaft, outer tube, observation port and so on. The driving device is composed of motor, reducer, coupling and so on. The oblique installation angle of the large inclination screw conveyor is generally about 4 °, and the length is generally not more than 8 meters. In order to avoid excessive bending of the screw shaft and friction with the outer tube, the middle of the screw shaft should be supported, and the degree of winding should be checked. The intermediate support is set to reduce the radial winding of the screw conveyor shaft, and the working conditions in this part are bad. Because the spiral blade is interrupted at the intermediate support, the length and lateral dimension of the support along the axis should be reduced as much as possible to prevent the material from clogging here. The support here can take the form of bearing or flange bearing. Each suspension bearing of the screw conveyor should reliably support the connecting shaft, and the screw shall not be jammed or bent. The suspension bearing should be installed at the center point of the connecting shaft, and the gap between its end surface and the end surface of the two spiral tube shafts should be greater than 10mm. In order to adjust the cumulative error of the length between the casing and the spiral, it is allowed to add pads between the flanges of each casing during installation. When the difference between the center height of the low-speed shaft of the speed reducer of the driving device and the center height of the screw conveyor is too large, the height of the driving device can be adjusted by the shim. During the no-load test run, if the bearing is found to have oil leakage, the bearing should be removed and the tightness of the spring in the seal ring adjusted until there is no oil leakage. The temperature rise of each bearing during no-load test run should not exceed 20 ℃; if the temperature rise is too high, it indicates that the location of the suspension bearing is improperly installed, resulting in the phenomenon of jamming of the connecting shaft. During load test, the temperature rise of each bearing should not exceed 30 ℃. In order to prevent the tiny particles of materials from entering the bearing, reliable dustproof and lubricating facilities should be adopted here. The screw conveyor is very sensitive to overload and is prone to blockage. In order to achieve a better conveying state, the pitch of the screw shaft is best to adopt a variable pitch. The pitch of the lower half is smaller than the pitch of the upper half. This structure prevents the material from being overloaded and clogged.

2020 09/24

- Wishes in 2022We at Ever Lucky Machinery wish you ever-lucky in New Year! Because of the covid-19 situation, it is hard for most of people this year. However, thanks to the hard work of all our staff, and support of all our esteemed customers, our sales performance improved much and met our key milestone. Our new workshop is in building process, which will release much more production capacity in new year. May this new year bring you closer to all those who you treasure in your heart, and we hope you have a happy and prosperous 2022.

2022 01/07

- Working principle of pulse bag filterThe pulse bag filter is when the dust-containing gas enters the pulse bag filter from the air inlet, first hits the sloping plate and the baffle in the middle of the inlet and outlet, the airflow turns into the ash, and the airflow slows down. Due to the inertia, coarse particles of dust in the gas flow directly into the ash bucket. As a function of pre-dusting, the airflow entering the ash bucket is then folded upwards and collected through the filter bag dust containing the metal skeleton inside, and is collected on the outer surface of the filter bag, and the purified gas enters the upper cleaning chamber of the filter bag chamber, and is collected. When the tuyere is discharged and the dust-containing gas is purified through the filter bag, the dust accumulated on the filter bag increases with time, and the filter bag resistance is increased, so that the treatment air volume is gradually reduced, and the normal operation is to be controlled.

2021 11/25

- Bag filter dust collectors are widely used in petrochemical metallurgy thermal power pharmaceutical lubricating oil paint waterThe bag filter is widely used in petrochemical, metallurgy, thermal power, pharmaceutical, lubricating oil, paint, water treatment, food, beverage, industrial dust removal and other fields.

2021 11/02

- Simulation of no-load test of bag filter dust collectorFirst of all, one by one to check the solenoid valve, exhaust valve, feeder, screw conveyor line and the valve open and closed normally, then press the timing control time, according to electronic control procedures for the entire process of cleaning the room.

2021 10/08

- Portable Bag Filter Dust Collector - New Star of IndustryAs a new type of filter, the mobile bag filter has a special internal structure. The metal basket supports the filter bag, the liquid flows from the inlet, passes through the filter bag and flows out of the outlet, and the filter bag can be used again to replace it. Mobile bag filters are mainly divided into: top-in single-bag filters and side-into-bag filters, while the top-in single-bag filter consists of a patented loop-type filter bag and related accessories. Its main advantages: 1. Large filter area 2. Easy to replace filter bag 3. Good sealing 4. Easy to install and debug 5. Small structural stability error.

2021 06/01

- Select dust bag (filter bag) according to cleaning methodThe dust removal method of the bag filter is the primary condition for selecting the type of dust bag (filter bag). It can first determine whether the dust bag (filter material) is a woven fabric, needle felt, compressed felt, or dust bag (glass fiber filter bag). As for the detailed specifications of the dust bag (filter bag), further consideration can be given based on other filter conditions.

2021 05/06

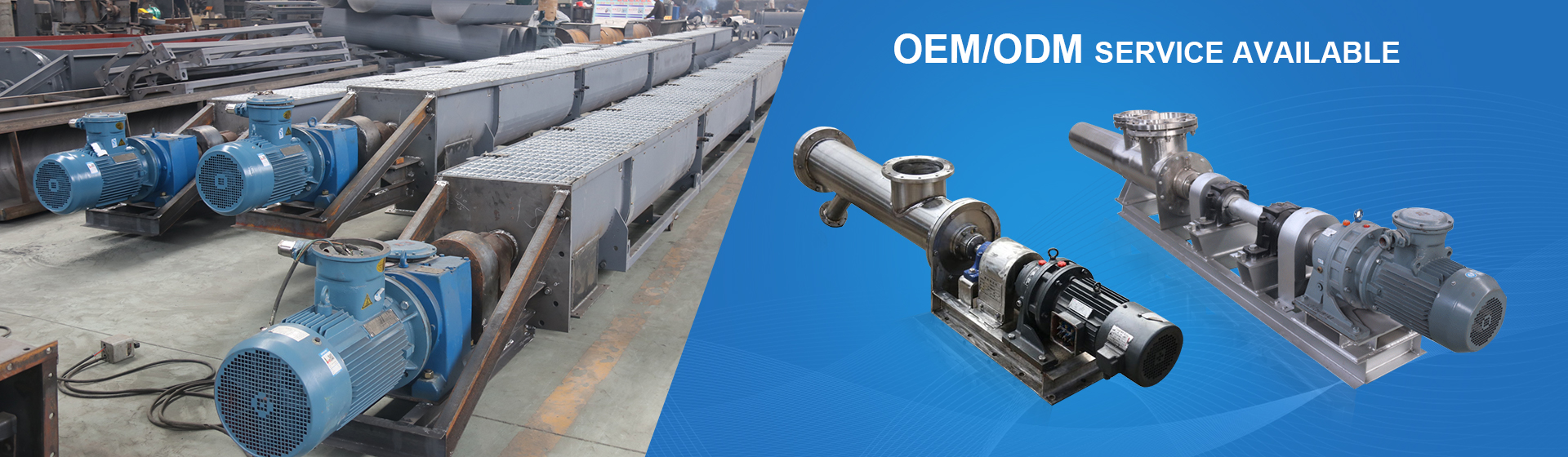

- Belt conveyor productionEverlucky Machinery manufacture and supply belt conveyors for various industries globally.

2021 03/22

- High temperature dust collectionOne of the most common concerns in the history of bag filters is their ability to handle very high temperature dust gases, which is one of the reasons why electrostatic precipitators have become so popular in power plants, cement plants and other industries. In addition, it is more concerned that high-wear dust is likely to cause premature damage to the filter element (this problem is rarely found in electrostatic dust removal technology). When formulating the electric bag change plan, this issue should be fully considered and a feasible corresponding solution can be proposed.

2021 03/15

- The main components of a bag filter dust collectorThe bag filter system mainly consists of a filter container, a support net and a filter bag.

2021 03/11

- Performance of PPS filter for bag filter dust collectorCharacteristics: density 1 389/cm3, breaking strength 5 09/dt limiting oxygen index 34, is a crystalline high-performance thermoplastic engineering plastic with heat resistance, chemical resistance, flame retardancy and other characteristics

2021 02/02

- PPC/MC bag filterThis series of bag filters are internally mirror-polished to meet hygienic requirements, and the outer and support baskets are made of sanitary stainless steel (SUS304). The advantages of the trap: high flow capacity, long service life of the filter bag, uniform liquid flow, even distribution of particulate impurities in the filter layer of the filter bag, high efficiency filtration, within the filtration fineness range of 0.5 to 100 microns The cost is low. two. Application areas: Food and beverage: precision (sterilization) filtration of liquids such as beer, wine, fruit wine, rice wine, juice, beverages, dairy products, edible oils, and seasonings.

2021 01/25

- University students research and development bag filter efficiency of 99.5%It is understood that bag filter is recognized as the most efficient dust collector at home and abroad, is to reduce the most effective PM2.5 equipment. However, the bag filter can only filter non-stick PM2.5 fine particles, there is no way for sticky particles. The Ningbo University PM2.5 this capture device, not only can efficiently filter non-stick fine particles, but also can filter sticky particles. Li Peng, a team of five people told reporters, PM2.5 capture device is actually to improve the bag filter, the principle is not complicated, is to filter the exhaust before the bag surface covered with a layer of unique powder, due to The effect of powder physical filtration and powder adsorption can effectively isolate the sticky particles in the tail gas and change the situation that the original bag filter clogs the scrapped particles when they are sticky particles. According to the experiment, when the bag is not pre-paved, the service life of the bag is only 420 minutes, while the trapping device with a layer of man-made powder filter aid is still intact after 30 cycles and the estimated service life is 2-3 years , The use of cost greatly reduced. At the same time from many experiments, with the addition of powder, the average sub-micron particle filtration can be as high as 99.5%.

2021 01/11

- We are presenting a live stream of factory tour on Jan 8th 2021On Jan 8th 2021, Friday, we are holding an online live show of our factory and works for the first time. Online entrance of the live will be noticed by email. Products to display: Screw conveyor, Bag filter, Bucket elevator, Scraper conveyor, Ventilation valves, Rotary airlock valves etc.. Welcome to the online tour.

2021 01/04

- Work efficiency of horizontal screw conveyorThere are many parameters affecting the horizontal screw conveyor, including the conveying amount, filling rate, pitch, screw shaft speed, spiral diameter, etc. Each parameter affects each other and restricts each other. In particular, some of the main parameters have a very large impact on the production efficiency, service life and performance of the conveyor during horizontal transport. Delivery volume Delivery is a very important indicator of horizontal spiral delivery capacity. The delivery volume is generally given according to the production needs, but it is also closely related to a series of parameters such as the filling factor, the pitch, the screw shaft speed and the like. When the material is transported in a horizontal spiral, although the volume occupied by the screw shaft has a certain influence on the conveying amount, the influence is small, and therefore, the influence of the volume occupied by the screw shaft on the material conveying is ignored here. 2. Screw shaft speed The rotational speed of the screw shaft has a large influence on the amount of horizontal spiral conveyance. Generally speaking, the larger the rotation speed of the screw shaft, the larger the conveying amount of the horizontal spiral, and the smaller the rotation speed, the smaller the conveying amount. However, the rotation speed of the screw shaft cannot be increased without limit, because when the rotation speed exceeds a certain size, the material will roll due to the centrifugal force that is received too much, and the rotation speed of the material just appears to be the limit rotation speed. If the material does not roll during transport, the centrifugal force of the material is not large enough.

2020 12/28

- Shaftless screw conveyor adopted in ceramic production lineDuring the production of ceramics, the transportation of raw materials is an important part of the production process. Due to the large moisture content of the ceramic materials, the traditional transportation equipment has certain limitations in terms of material adaptability and on-site location arrangement. Introduce a conveyor for non-shaft screw conveyor which is suitable for ceramic materials. Because of its non-central shaft structure, the steel screw body is directly connected with the transmission device and can be made into a cantilever structure, especially adapted to the rotation of ceramic particles. The kiln tail material is fed into the kiln

2020 12/21

- LS type screw conveyorFeatures: LS type screw conveyor adopts DIN15261-1986 standard, designed and manufactured to meet the professional standard of JB/T7679-45 "LS type screw conveyor", LS type screw conveyor is U-shaped and its spiral diameter is 100~1250mm, total ten A specification, divided into single drive and dual drive. The single-drive screw conveyor zui has a large length of up to 35m, of which the LS1000 and LS1250 type zui have a large length of 30m. The intermediate suspension bearing of the screw conveyor adopts two structures of rolling and sliding interchangeable, with small resistance, strong sealing and good wear resistance.

2020 12/16

- MC/MZ/MS series buried scraper conveyor1. Use a single high-strength mining ring chain to drag the scraper and drive it with a concave-toothed sprocket, which has the characteristics of large load capacity, long chain life and high strength. 2. The chain can be automatically tensioned to ensure that the chain is always in a moderately tensioned state for a long time, eliminating the need for manual and frequent and intense operation. 3. The chain and scraper return section is supported by the supporting wheel, which not only saves labor and reduces wear, but also helps the automatic tightening and sliding of the chain through the automatic change of the deflection between several rollers. 4. If the driving mechanism is self-contained with the casing at the upper part of the machine head, the whole installation can be operated freely without using the anchor bolts. 5. The running speed can be controlled by YVP series motor and inverter combination, which is the international advanced speed control mode. 6. The feeding mode adopts the large size on both sides to enter through the split flow, so that the return chain and the scraper are separated from the feed, and are conveyed forward with a constant large-size layer thickness. The phenomenon of returning the chain and scraper to the material no longer occurs.

2020 12/08

- Scraper chain drag chain conveyor operation guideProper and skilled operation of the buried scraper conveyor can not only improve work efficiency, but also ensure the safety of the operator and reduce safety accidents. The precautions for operation of the scraper conveyor should be affixed to the position easily visible to the operator and always remind the correct use of the scraper conveyor. 1. The scraper conveyor driver shall be trained and certified, take charge of the knowledge of the structure and performance of the scraper conveyor, know how to operate, and regularly maintain the machine. 2. When the driver receives the start signal from the tail end, he must contact the pre-equipment to determine whether the pre-equipment is operating normally. 3. Check the equipment and check if there are no problems before starting to drive. 4. Perform jogging operation on the equipment. After the jogging, there is no problem and normal operation can be performed. 5. During the operation of the equipment, the driver should pay attention to the observation at any time. If the abnormality is abnormal, it should be handled in time. The temperature of the machine bearing should not exceed 75 degrees Celsius. For the chain, pay attention to whether the chain, card chain or skip chain phenomenon. 6. If the machine is abnormal, it should be stopped immediately and can be continued after troubleshooting. 7. After the machinery and equipment are shut down, the driver should clean up the machinery and equipment, and record the problems in the operation of the machinery and equipment for future reference. 8, maintenance should be carried out in the case of power failure, and hang warning signs. 9. Do not start the device frequently to avoid damage to the device. 10, if the driver is not very clear on the signal, then you can not boot operation. 11. The handover work should be done well. The necessary handover should be clear and the handover record should be made. 12. Before stopping the machine, the material on the conveyor should be emptied to avoid starting the load of the conveyor.

2020 12/01

SEE MORE

Email to this supplier